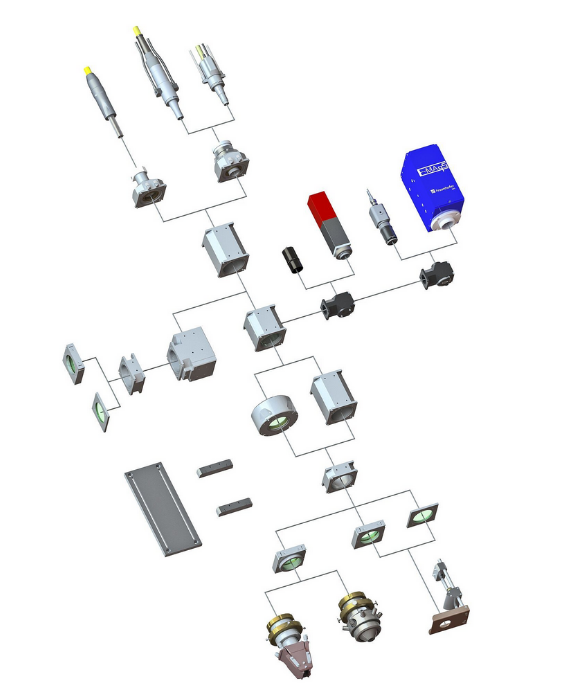

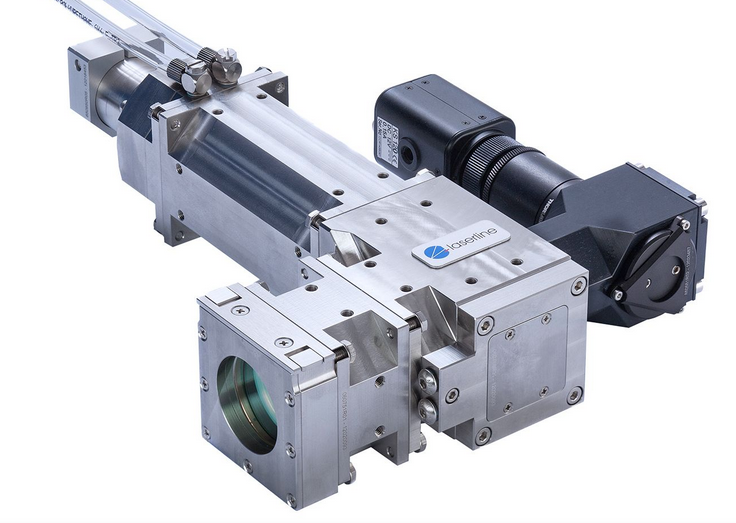

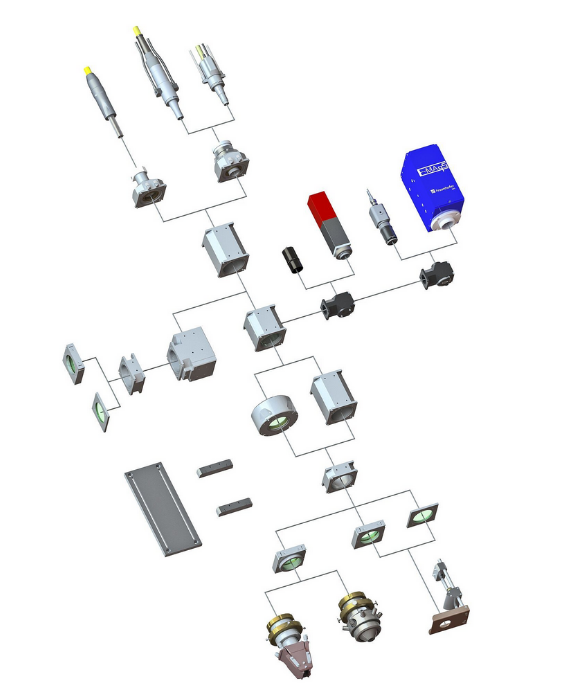

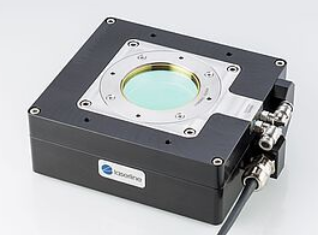

Laserline OTS optics are designed for industrial material machining in combination with Laserline diode lasers. Due to their modular design and the wide variety of spot geometries that can be produced, these optics can be configured flexibly and optimally to meet the most varied process requirements.

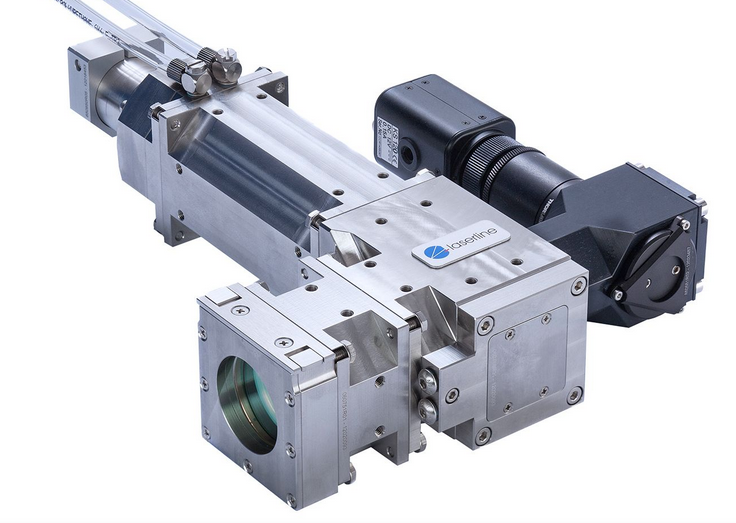

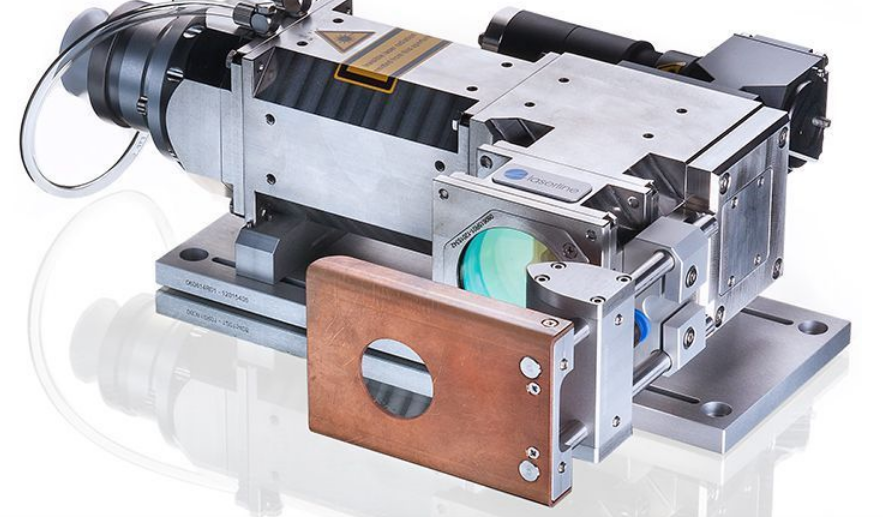

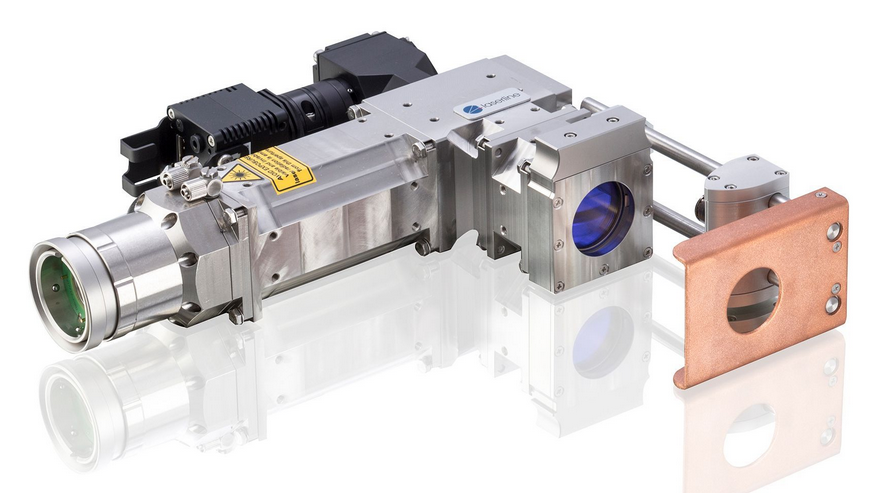

Internal cooling as well as an anti-corrosion stainless steel body with an IP54 protection rating allow the optics to withstand continuous use conditions in highly dusty and humid production environments at high powers up to 20 kW.

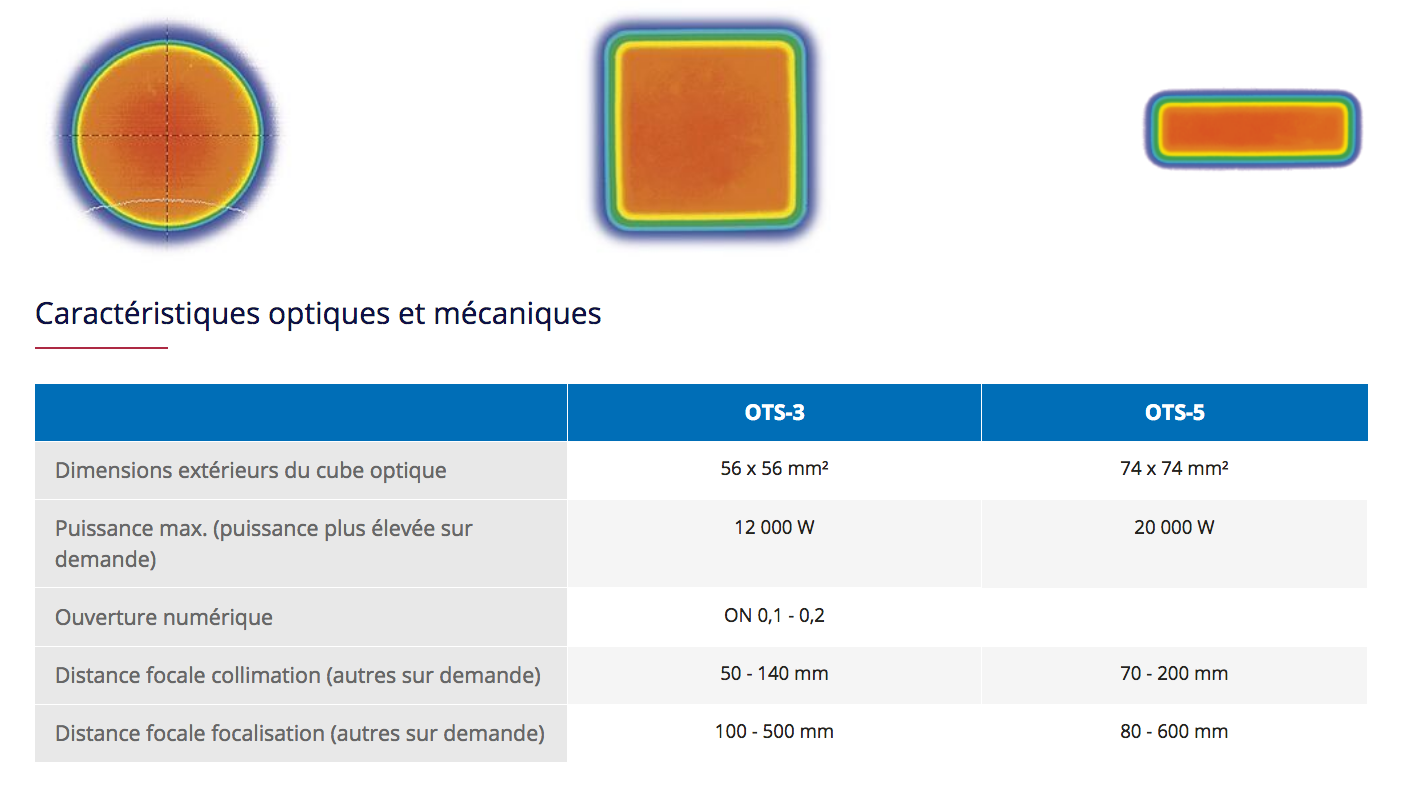

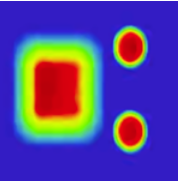

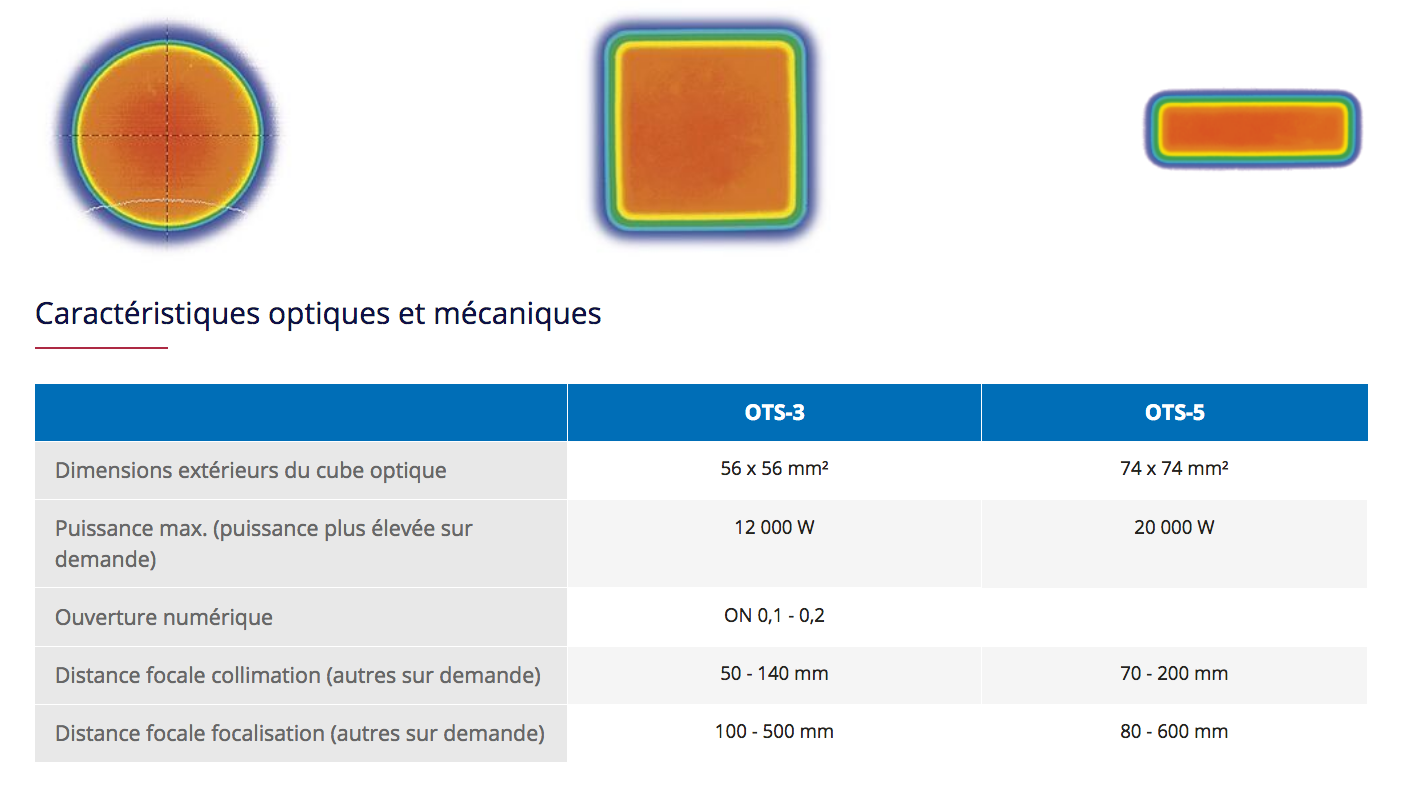

Whether they are round or elliptical spots for welding, high power soldering or hardfacing, applications linear or rectangular spots, Laserline OTS optics have been developed to meet the requirements encountered in industrial laser applications.

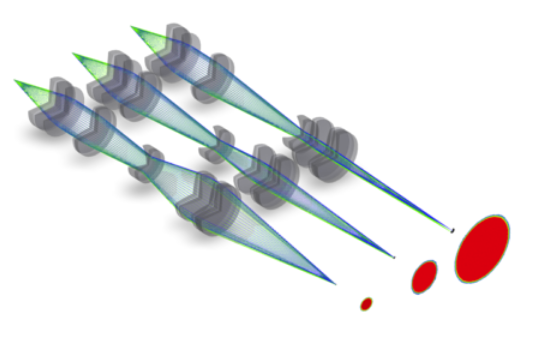

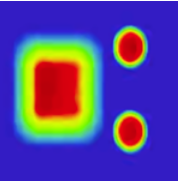

For special applications like simultaneous welding, specific configurations like double spot or ring spots are also possible.

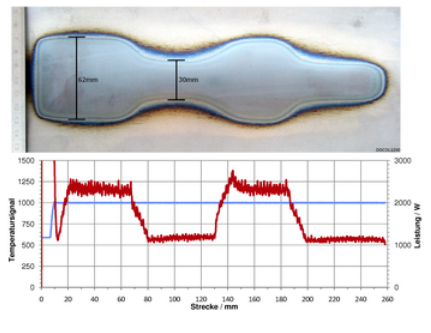

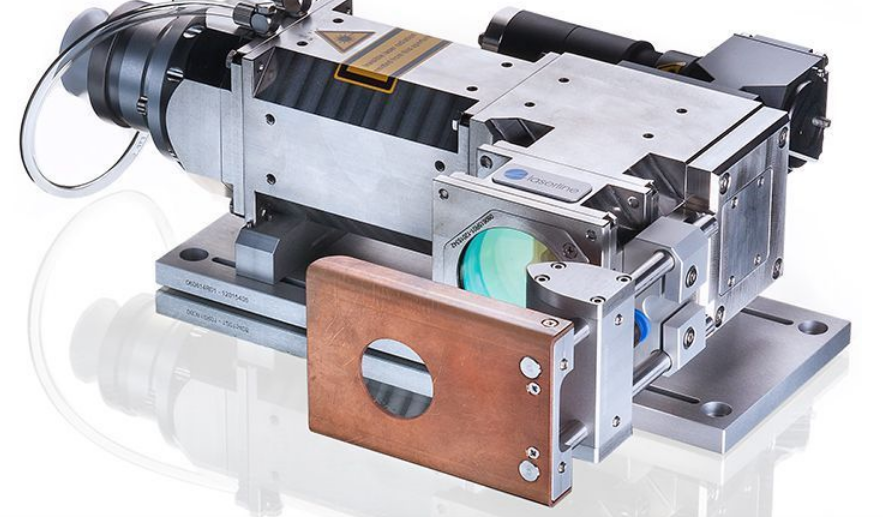

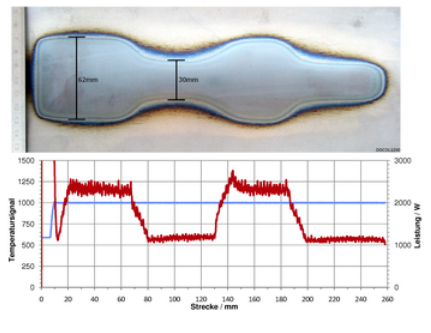

Laserline welding optics meet the most severe industrial requirements. They are specially adapted to Laserline diode lasers, which allows machining results meeting the most stringent quality requirements. When process conditions are complicated, sensors or monitoring systems can also be integrated.

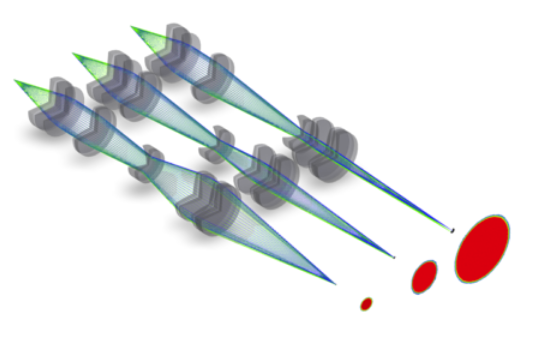

Laserline brazing optics make it possible to produce cords that meet the most severe requirements of the automotive industry. When high-power brazing of galvanized sheets, the pre-spots remove the zinc layer along the brazing bead, resulting in high quality results at high brazing speeds.

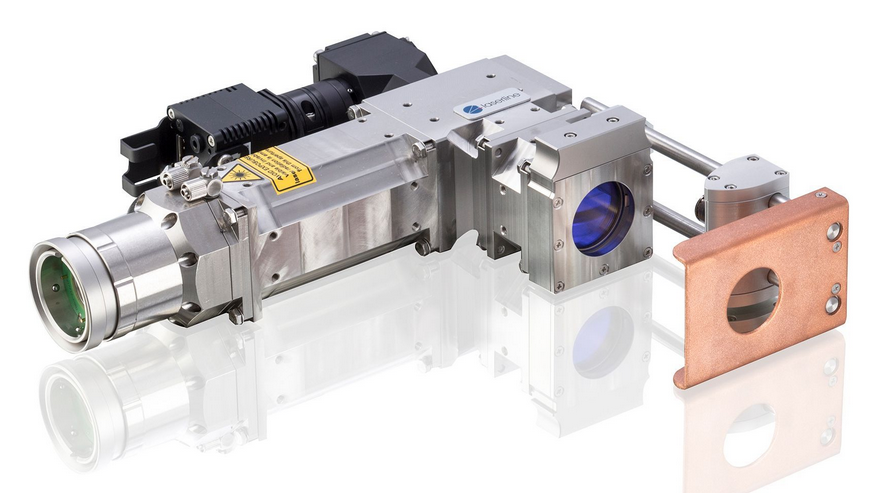

Laserline optics can be fitted with homogenizer modules. The geometries of the laser spots thus obtained (squares, lines, rectangles) have a linear and homogeneous profile particularly suited to applications such as laser hardening and surface treatment in general. Depending on the requirements of the process, it is possible to mount accessories such as a camera, pyrometer and other monitoring devices on these optics.

Laserline also offers Zoom optics allowing dynamic adaptation of the spot geometry during the process, variable from 5m to 175mm on both axes.