Industrial Laser Systems

A professional and passionate team at your service

Based in the Paris region, Industrial Laser Systems is a French manufacturer of laser machines and integrator of laser sources. Our design office is at your disposal to study with you your laser welding machine, laser cutting, laser additive manufacturing, laser texturing...

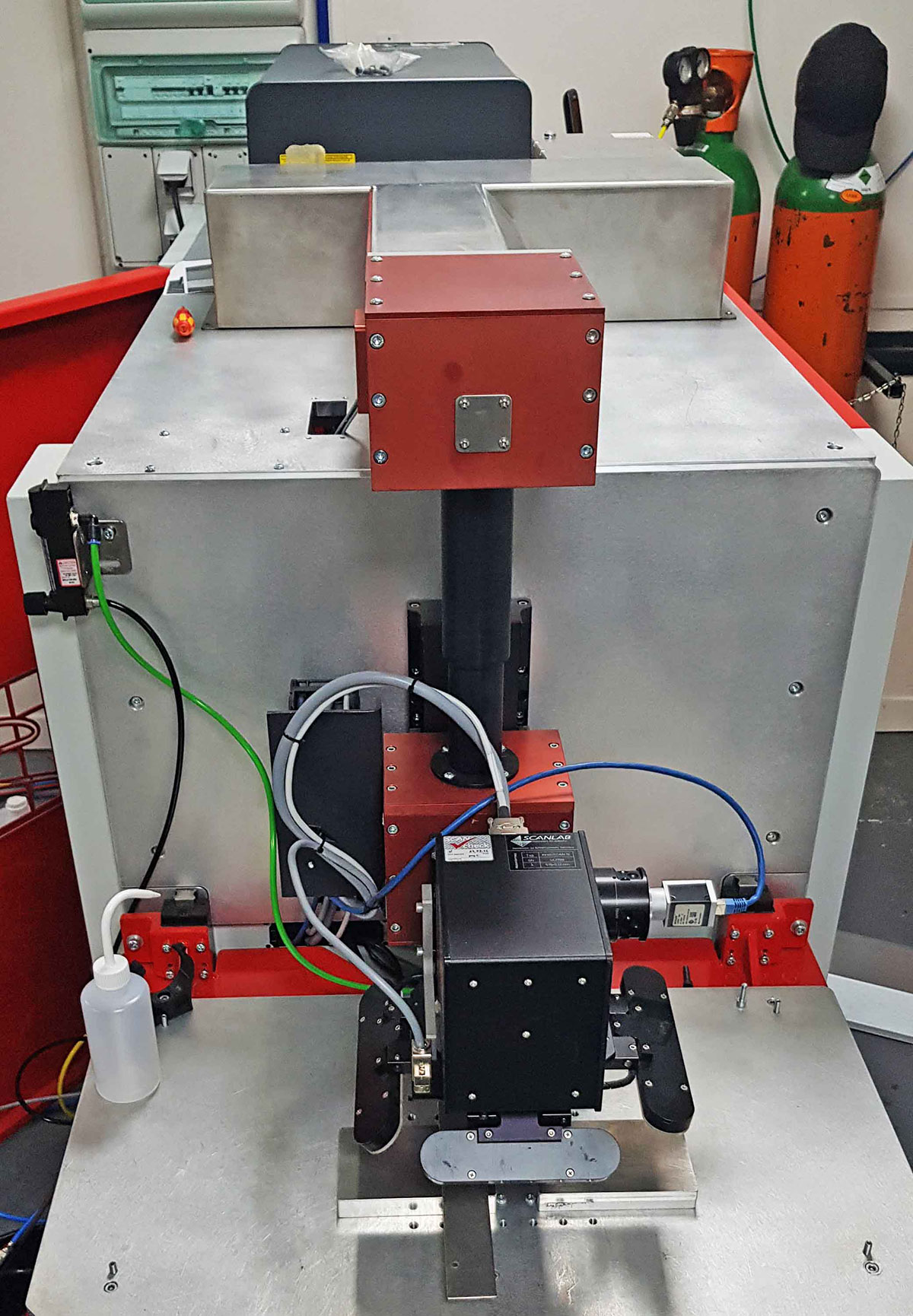

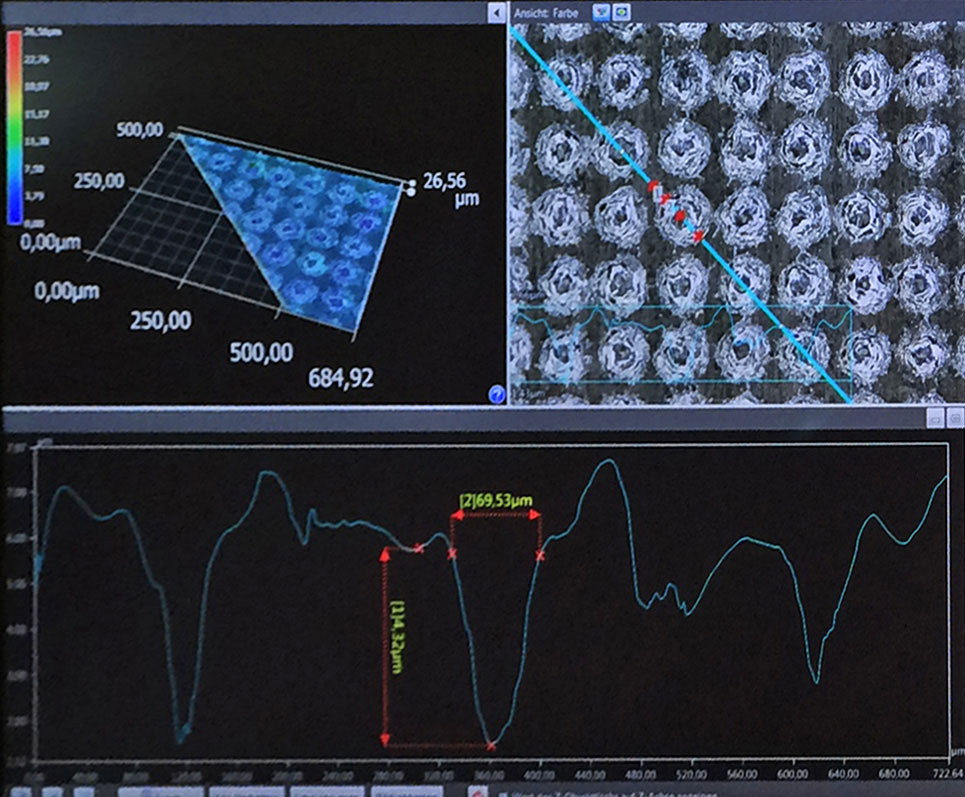

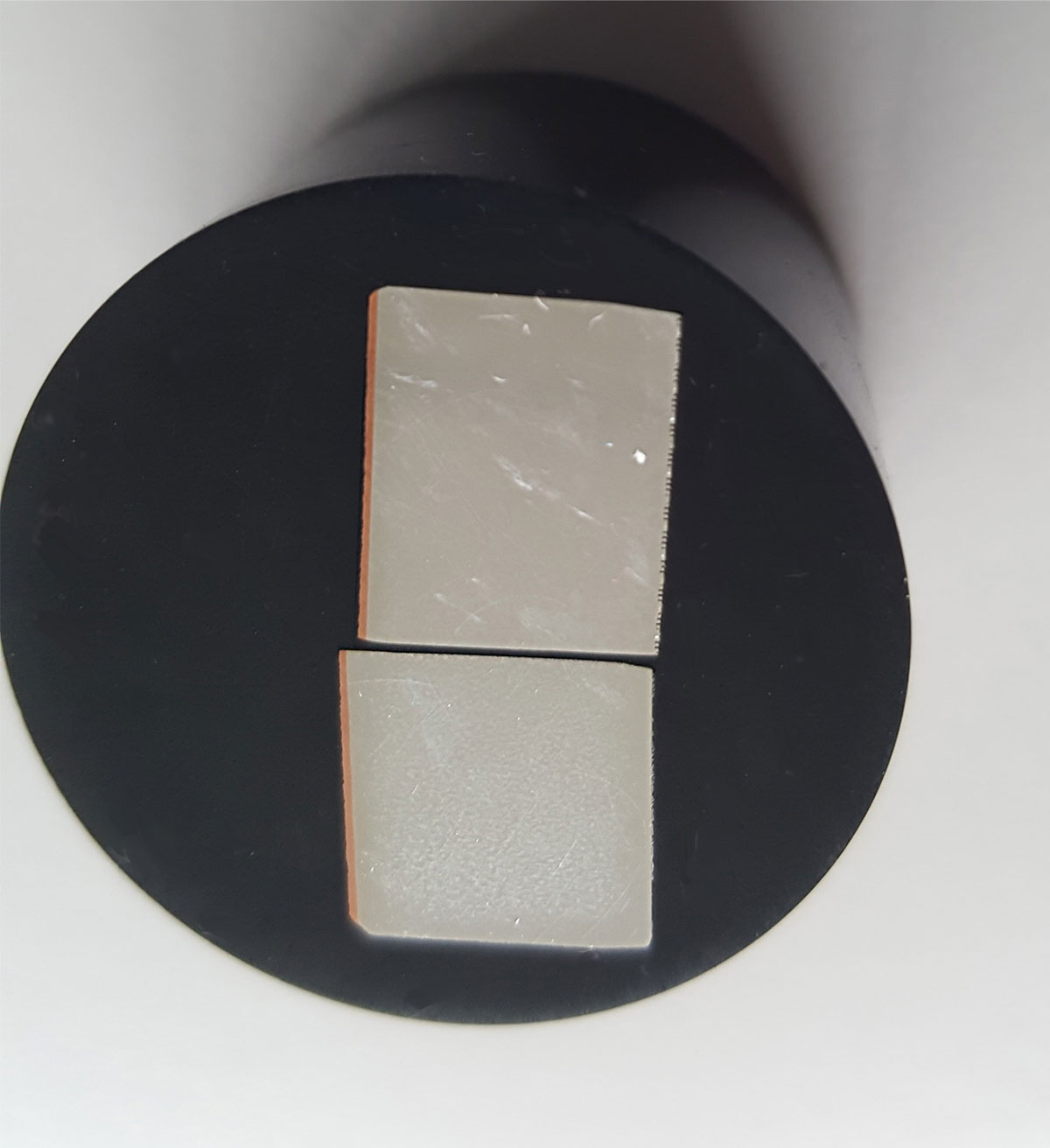

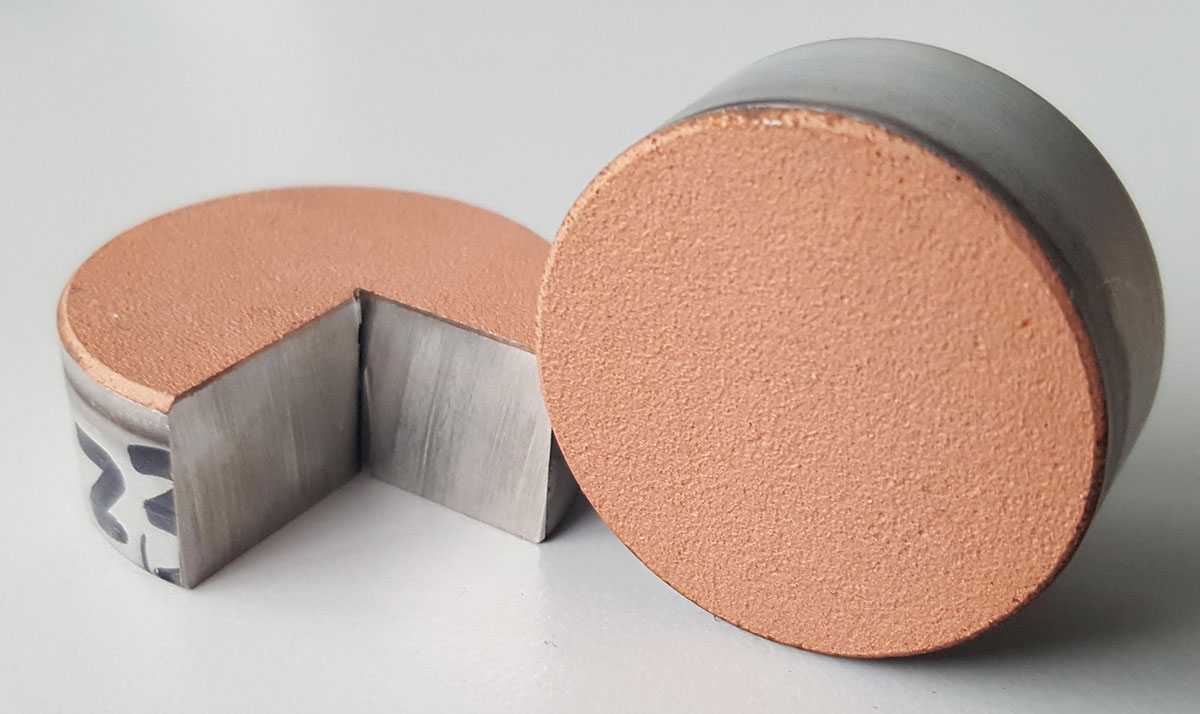

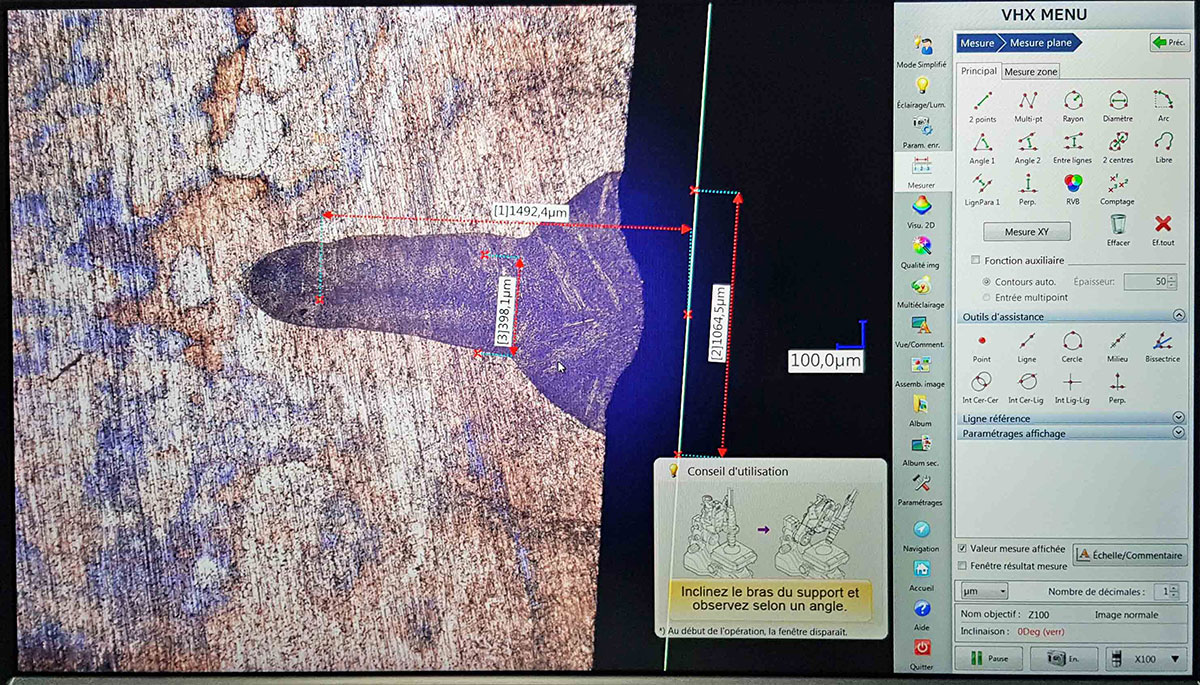

The Industrial Laser Systems laboratory has several types of laser sources and various means of measurement and analysis to carry out with you the validation tests that will allow you to define and size your laser machine.

Since 2003, we have been equipping the automotive, aeronautics, medical industries and many others. Our laser machines are installed in Europe but also in Asia, India and the United States. We provide service and training for all the machines we install.

The partnership we have with renowned laser specialists allows us to offer industrial, robust and innovative laser machines.

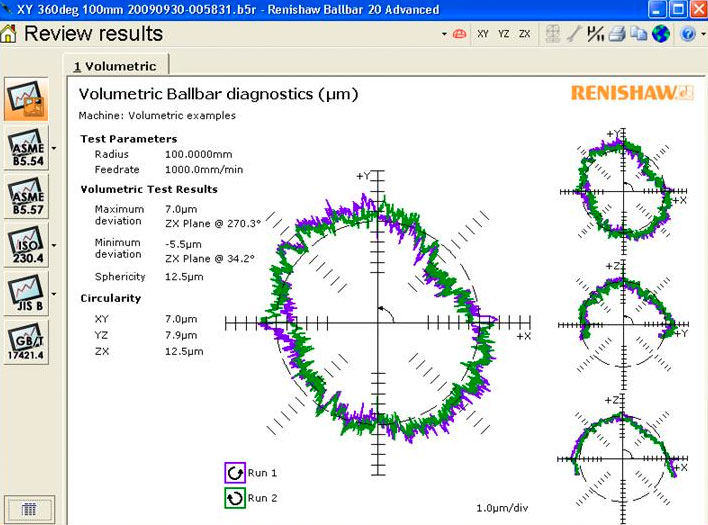

Renishaw Ball bar

Renishaw measurement reports

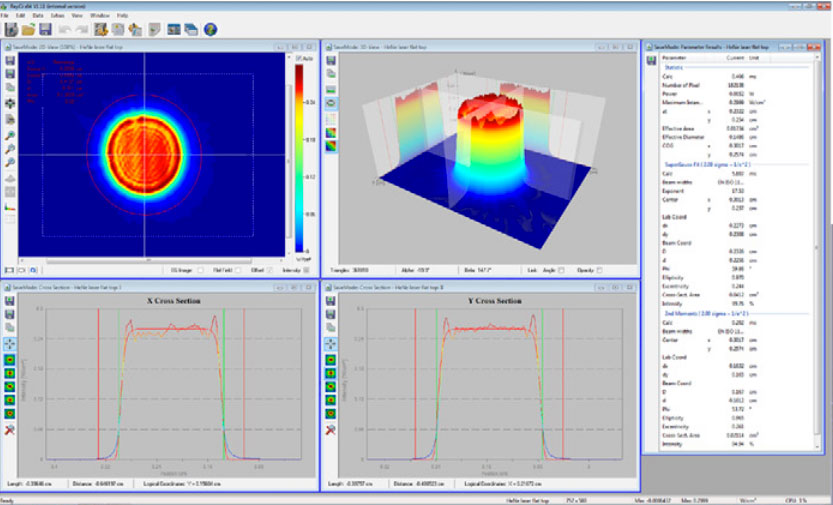

X,Y galvo configuration with vision

UV, visible and IR lasers, femto and nano sec

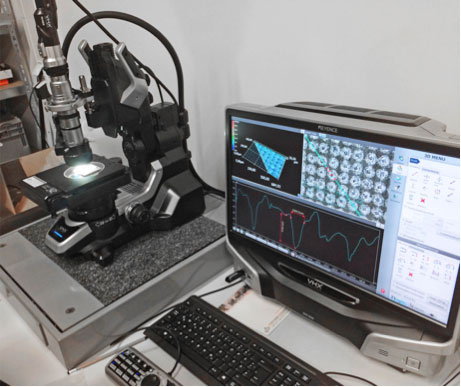

Grinder, polisher and press for producing metallographic samples

Image of a metallographic section of a nail head weld