Diode lasers generate laser light in a semiconductor wafer, which is supplied with energy by an electric current. These laser diodes called semiconductors are used in different configurations. There are solutions in which individual laser diodes are used (single emitters) as well as mounting several of these laser diodes on a so-called "diode bar".

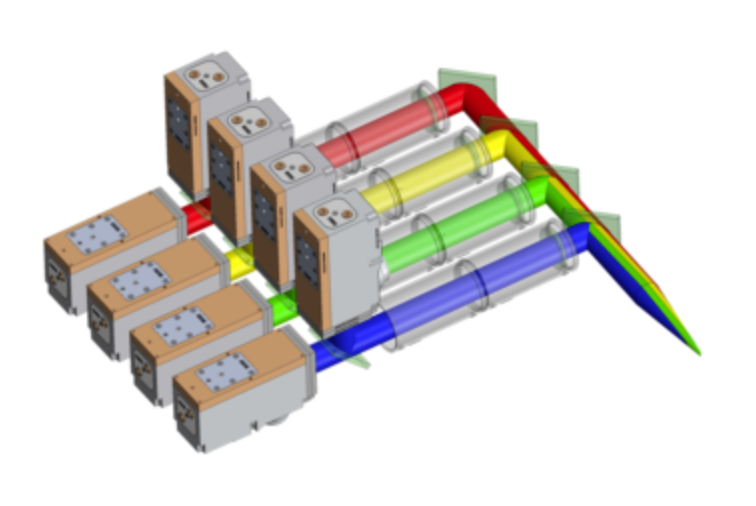

To transform a laser diode into a diode laser system, several bars are stacked on top of each other and several stacks are optically combined. In this way, power can be scaled from a single laser diode to high performance systems. Laserline high power diode lasers are designed according to this principle and only bars are used.

The wavelengths used range from 900 nm to 1080 nm for a power of up to 45 kilowatts.

An important parameter of lasers for industrial use is their efficiency (electrical efficiency). It describes the amount of energy supplied which is converted into light and emitted as a laser beam. While some lasers convert only a few percent of the supplied energy into laser light (CO2 laser, Yag laser, etc.), Laserline diode lasers achieve an efficiency of up to 50% (diode to part).

This is mainly due to the fact that the conversion of electric current in a laser diode reaches almost 70%. This is the main reason for the success of diode laser sources, in industrial production for more than 20 years.

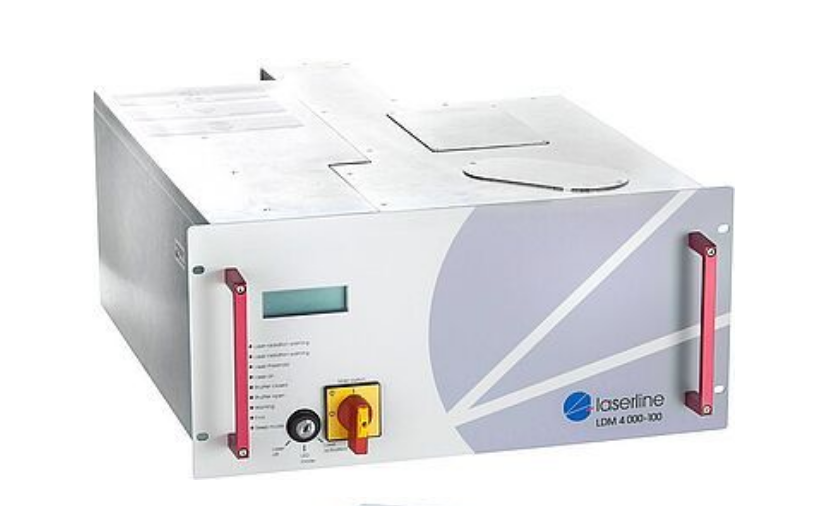

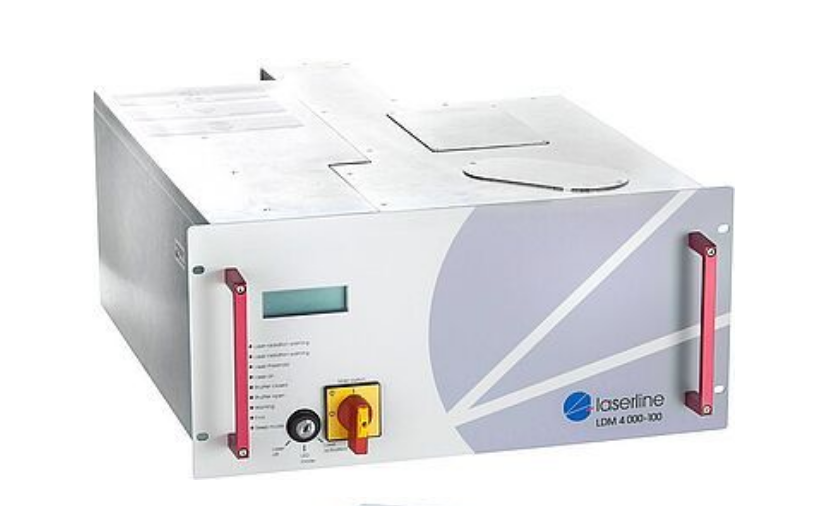

In a 19-inch rack, its compact design facilitates the integration of the LDM diode laser for plant builders, thus qualifying it as a standard industrial tool. Whether in a classic control cabinet, in an operator station or under the conveyors of a production plant, its innovative design allows the LDM diode laser to be integrated into any production area. It does not require any additional space and is therefore ideally suited for OEM applications.

LDM Laserline diode laser module from 1kw to 8 kW LDM Laserline diode laser module from 1kw to 8 kW The LDM diode laser series is available from 500 watts up to 8,000 watts always in a 19 inch rack. Laserline LDM diode lasers can be equipped with different types of optical fibers and optical accessories such as zooms, welding optics, homogenizing optics, etc.

The LDM blue diode laser revolutionizes the processing of copper, gold and other highly reflective metals in multiple ways. The direct generation of laser power of up to 2 kW cw at the wavelength of 450 nm is unique and thus avoids complex and inefficient wavelength conversions.

The absorption, and therefore the efficiency of the process, is increased by a factor of up to 20 compared to lasers in the 1 micron wavelength range. The precisely controllable energy deposition of the diode laser allows the melting of copper without evaporation, leading to unmatched stability of the weld pool.

This opens up new application possibilities, such as heat conduction welding of thin copper foils, additive manufacturing, surface treatment with large homogenized spot.

Combinations of different metals can be made with copper as the first junction material, for example copper and aluminum or copper and steel, breaking the convention that copper should be the bottom junction material.

The Laserline LDM Blue diode laser is today the only laser in the world with such laser power in this wavelength range, ie 2000 watts at 450 nm.

With the LDF series, Laserline sets the benchmarks for high power diode lasers. Even sources with a laser power greater than 20 kW are installed on sturdy casters allowing a single employee to move the laser to different locations for production start-up - a unique advantage.

All you need is electricity, water, and an optical fiber - and the laser is ready for use at its new site.

Thanks to the continuous development of Laserline's proven active diode cooling technology, the LDF series family is optimized for power levels of several kilowatts, even at high beam qualities: 8 kW on a 600 µm fiber at NA 0.1 in a compact configuration occupying less than one square meter foot print.

Whether it's power, cooling or system interfacing, the LDF series can be individually configured to meet changing needs. The LDF laser series is available with internal or external cooling. With these Laserline coolers, specially developed for the range and fully integrated into the control cycle, high power lasers can now operate continuously in production with a small footprint. Thanks to the internal networking of all components, malfunctions can be diagnosed in real time and resolved immediately.

The LDF series is one of the most efficient laser technologies with up to 50% electrical efficiency. Thanks to the mobile hot-plug control unit, LDF lasers can be flexibly monitored and controlled, even from a distance. Individual components can be easily replaced thus reducing production interruptions.

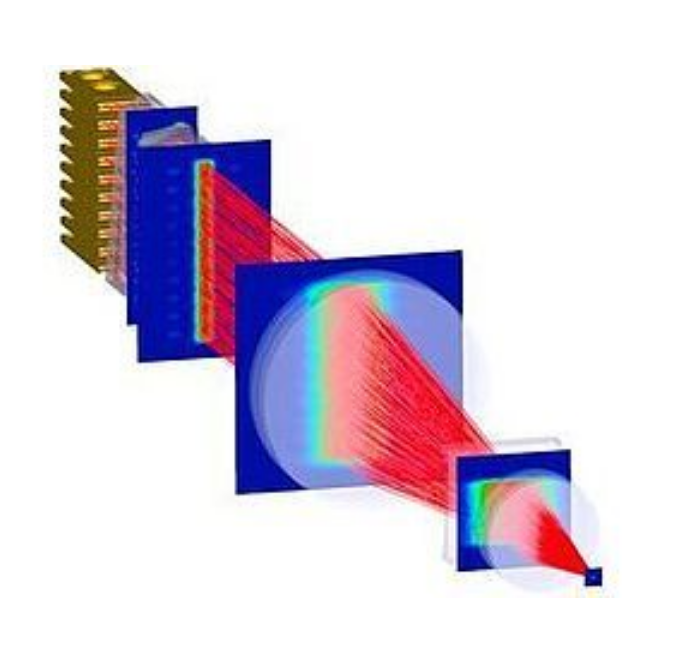

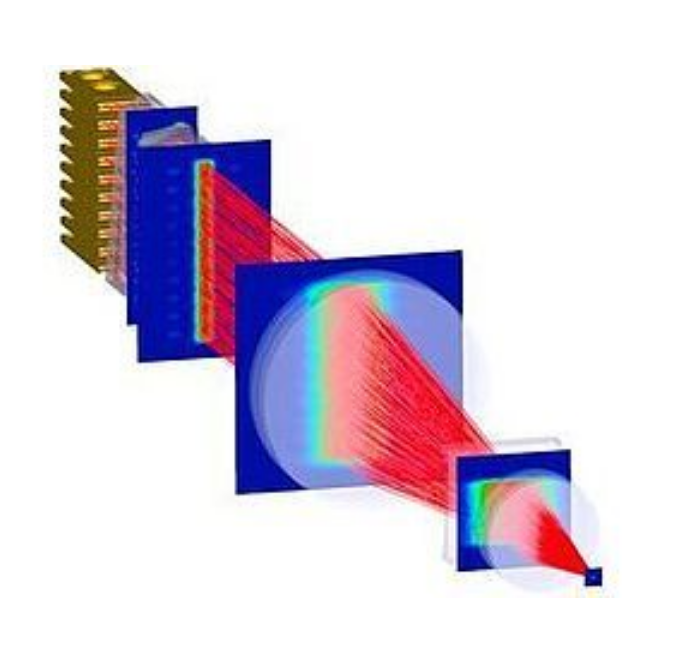

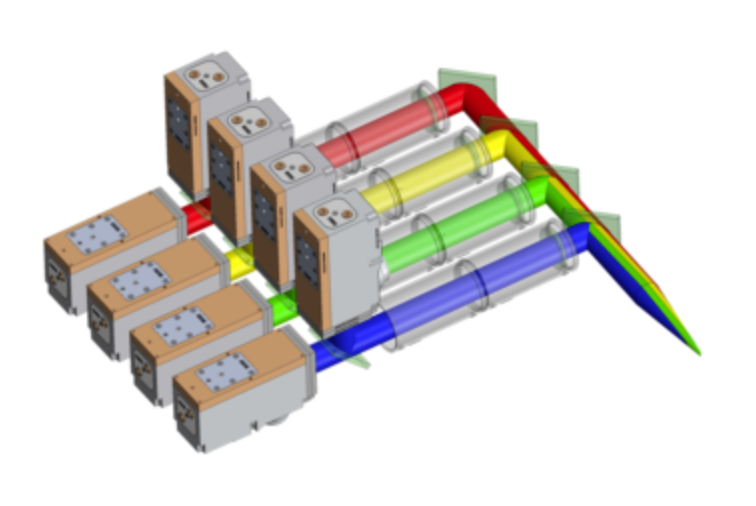

The laser beam source contains several stacks of individual diode arrays. The number of arrays per stack and the total number of stacks depend on the laser output power and the required beam quality.

Using simple, patented technology, the diode beams are superimposed to form a single laser beam which is coupled into an optical fiber.